Streamlined Cementing: Packard’s Practical Innovation

Need content: This would significantly enhance operational efficiency and reduce the rig’s non-productive time (NPT).

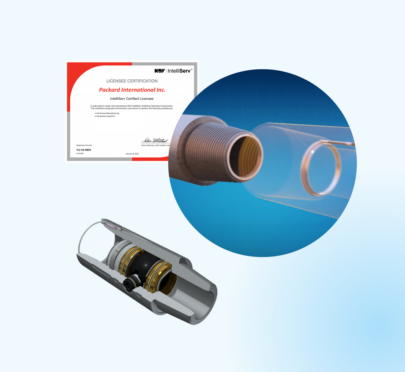

Product Details

- Need content

In Collaboration with

Challenge: Streamlining Cementing Operations

In 2016, a major Eagle Ford producer faced a critical challenge. If a valve could be strategically placed above the production casing during cementing, then the rig could be skidded to simultaneously drill the next hole. This would significantly enhance operational efficiency and reduce the rig’s non-productive time (NPT).

Exploration: Collaborating with the customer’s team

Packard collaborated closely with the producer’s wellhead manufacturer and service provider. Together, they designed a specialized valve that would seamlessly integrate into their existing cementing equipment.

Solution: The Skid-Enabled Valve

The result of their joint effort was a custom valve, strategically positioned above the production casing that allowed the rig to skid before the final cementing crew arrived. Packard’s focus on an efficient and practical solution slashed rig NPT, optimized resource utilization, and streamlined the entire cementing operation for our customer.