Packard’s Slotted Ball cuts through a core problem

Need content: The goal was to find a solution that would enable precise ball release while maintaining valve integrity.

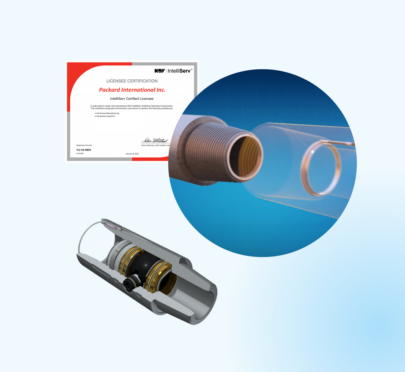

Product Details

- Need content

In Collaboration with

Challenge: Adapting Kelly Valves for Downhole Coring

In 2015, a customer in the coring field faced a unique challenge. They needed to activate their downhole coring tool using a standard Kelly valve. However, the existing valve design didn’t allow for seamless ball drop activation. The goal was to find a solution that would enable precise ball release while maintaining valve integrity.

Exploration: Crafting a Slotted Ball

Packard stepped up to explore this challenge. We meticulously designed and manufactured a slotted ball as the solution. The ingenious modification allowed free mud flow through the valve even when the ball was in the closed position. The drop ball was strategically loaded on top of the valve ball, ready for action. The critical step was ensuring smooth actuation to the open position, allowing the ball to drop downhole and activate the core barrel.

Solution: Precision Activation

Now the slotted ball design seamlessly integrates with the Kelly valve. When the moment arrived, the ball could be precisely actuated to the open position, initiating the core barrel operation. Packard’s commitment to innovation and practicality ensured that downhole coring processes were efficient and reliable.