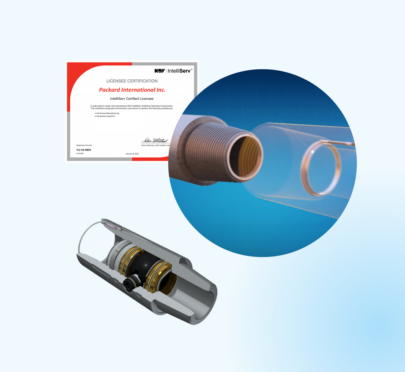

Corrosion No More: Packard’s Shielding Solution for Top Drive Valves

Need content: The rapid deterioration posed a significant challenge, impacting drilling efficiency and reliability.

Product Details

- Need content

In Collaboration with

Challenge: Premature Valve Failures

In 2017, a major drilling contractor faced a critical issue: top drive valves (from various manufacturers) were failing pressure tests within a month of operation. The rapid deterioration posed a significant challenge, impacting drilling efficiency and reliability.

Exploration: On-Site Investigation

Packard journeyed to the desert drillsite to investigate the root cause. Our findings revealed the extremely corrosive mud used in drilling was causing internal pitting within the valves. This corrosion, in turn, restricted the movement of the floating seats, leading to premature failures.

Solution: Valve Internal Plating

Field knowledge in hand, Packard developed a practical solution. They introduced an internal plating process for the valves. This protective coating acted as a shield against corrosive elements, significantly extending the valve’s lifespan. With routine 6-month servicing intervals valves could now withstand the harsh drilling environment for several years. Packard’s commitment to research and testing forged a lasting improvement in product durability and reliability for our customer.